Rubber Track Solutions

Jerry Von Gruenigen: V.P. Sales & Marketing

One of the most common questions we get from farmers and equipment owners is:

“What’s the difference between standard agricultural tracks and premium tracks – and when should I use each?”

It’s a fair question. After all, tracks represent a significant investment, and choosing the right one impacts everything from machine performance to long-term operating costs.

Let’s break it down.

Standard Tracks: Cost-Effective for Lighter Applications

Standard tracks are designed to be more affordable while still delivering reliable performance in the right situations. They work best on:

- Tractors under 400 horsepower

- Secondary tillage operations, such as pulling discs or harrows

- Planting, cultivating, or side-dressing applications

- Equipment that doesn’t see heavy ground loads or extreme drawbar pulls

If your machine is mostly doing row-crop work, minimal road travel, or lighter tillage, a standard track provides good value without overspending.

Premium Tracks: Built for Heavy-Duty Work

Premium tracks are engineered for longevity, durability, and high horsepower applications. If your operation involves:

- High-horsepower tractors (500+ HP)

- Primary tillage and deep ripping

- Scraping or dirt pan work

- Consistent heavy loads and maximum drawbar pulls

…then premium tracks are the right investment. They deliver longer wear, better resistance to fatigue, and superior performance under stress.

Some well-regarded premium options include:

- Camso 5500 and 6500 Series

- Trackman HP Extreme

- Firestone Class 6

- Camso DuraDrive with reinforced drive lugs

These premium lines feature stronger compounds and reinforced designs that extend life and performance in demanding field conditions.

Matching Tracks to Machine Types

Different tractors and applications call for different track choices:

- John Deere Legacy & 8RT Series: Standard tracks often suffice, but in heavy tillage or excessive roading, the Camso 6500 series is a better fit.

- Case IH 500+ HP Tractors: Tracks with reinforced drive lugs, like Trackman HP Extreme or Camso DuraDrive, are recommended.

- Friction-based systems (JD 8RT/9RT, Fendt Vario, Challenger MT700/800): Standard tracks can perform well under lighter loads, but premium tracks shine under high horsepower drawbar pulls.

Why Brand Matters

When it comes to ag tracks, brand quality is critical. Reputable names like Camso, Trackman, and Firestone consistently outperform low-cost, offshore imports.

Non-branded or bargain tracks often use softer compounds, wear out prematurely, and can’t handle high-horsepower applications. While they may look attractive upfront, they usually cost more in the long run due to shorter lifespans and more frequent replacements.

The Bottom Line

Think of it this way:

- Standard Tracks → Budget-friendly for lighter machines and everyday tasks.

- Premium Tracks → Higher upfront cost, but essential for heavy-duty, high-horsepower applications where durability pays for itself.

Investing in the right track for your machine not only improves performance but also reduces downtime and maximizes long-term value.

At Rubber Track Solutions, we help farmers match the right track to the right application—so you’re not overspending where you don’t need to, but you’re protected where it matters most.

Superior Tire & Rubber

Jerrod Ossa, Aftermarket Sales Manager – AgriTraxx® Undercarriage Wheels

In our last article, we broke down the essentials of undercarriage components—mid-rollers, idlers, and drive wheels—and how to keep them performing at their best. Now, let’s focus on the other half of the equation: the rubber track.

At Superior Tire & Rubber, we don’t manufacture or retread rubber tracks—but we’ve spent more than 20 years studying how they perform under real-world conditions. What we’ve learned is simple: the track you choose, and how you care for it, has a direct impact on uptime, performance, and operating costs.

A midlevel priced track, paired with proper alignment, tension, and wear checks, will serve most operations—tilling, planting, harvesting. For extreme or specialized applications, track selection becomes even more critical. Premium or heavy-duty tracks are designed to handle the high torque, weight, and ground conditions of tasks like pulling pan scrapers with tractors commonly seen such as Steiger QuadTrac, CAT Challenger, or John Deere 8RX.

In our research, we’ve also seen how undercarriage components can influence track life. While rubber wheels are common, AgriTraxx® polyurethane alternatives can reduce abrasion, lower heat buildup, and minimize debris damage—factors that can shorten a track’s service life. In demanding applications, that difference can be meaningful, but it’s not a substitute for choosing the right track from the start.

For producers aiming to maximize uptime and reduce costs per hour, the fundamentals remain the same:

- Match your track type to your application and conditions.

- Stay diligent with maintenance—alignment, tension, and wear checks are non-negotiable.

- Consider wheel designs and materials that complement your track choice, especially for high-stress environments.

Track selection isn’t just about price, it’s about aligning the right product to the right job, then protecting that investment through proper care.

If you’d like recommendations on where to source quality tracks, I can connect you with trusted aftermarket distributors nationwide.

Trackman

Tom Feldmann, Chief Manager of Engineering Development

Since the early 1990’s, Trackman tracks have been proudly manufactured at our St. Marys, Ohio plant – the same facility where we’ve produced military tracks since 1940.

Every Trackman track is built using proprietary rubber compounds, each carefully formulated to optimize performance in specific areas of the track – whether it’s the tread lugs, drive/guide lugs, or wheel paths.

Our tracks are engineered to meet the toughest demands on your farm, delivering superior traction, exceptional durability, and unmatched reliability. Whether your equipment uses a friction drive or a positive drive system, our mission is the same: to deliver peak performance and low cost per hour of operation.

Choosing the right track for your machine depends on your equipment type and specific application – and we’re here to help you find the perfect fit!

Friction Drive

If your tractor runs on a friction drive system, Trackman has the proven solution to keep you moving. Our friction drive tracks are built for rugged durability, reinforced reliability, and peak performance in the most demanding field conditions. Today, Trackman offers two friction drive options, HP and HP Extreme, each designed to meet the unique demands of different horsepower levels and field applications.

Built to Perform

Trackman friction drive tracks are engineered to deliver long-lasting performance with proprietary construction and materials that stand up to heavy-duty agricultural applications.

- Heavy-pull operations: Built for high-load, high-drawbar tasks

- Row Crop Precision: Smooth transitions and reduced vibration

- Demanding Terrain: Designed for durability in tough environments

Each Trackman friction drive track features:

- Fully Molded Tread & Guide Lugs: Superior wear resistance and reduced chunking

- Brass-Coated Cable: Enhanced corrosion resistance and extended lifespan

- MAXXTUFF™ Reinforcement: Premium strength and stability under extreme conditions

Better: Trackman HP

A trusted choice since the early 1990s, the Trackman HP track is ideal for standard row crop tractors and general agricultural use.

- 0″ Fully Molded Tread Lugs for traction and durability

- 25″ Heavy-Duty Carcass for high-load performance

- Molded Guide Lugs for smooth transitions

- Brass-Coated Cables for corrosion resistance

- MAXXTUFF™ Reinforcement for long-lasting strength

Best: Trackman HP Extreme

Introduced in 2018, the HP Extreme track is designed for tougher friction drive applications, including high-intensity tillage and construction-grade use.

- 75″ Fully Molded Tread Lugs for extreme traction

- 5″ Heavy-Duty Carcass for added structural integrity

- 5% Wider Tread Design for increased ground contact

- Open-Center Lug Configuration for self-cleaning and debris control

- MAXXTUFF™ Wire-Ply Construction for unmatched carcass strength

- Brass-Coated Cables for extended life in harsh conditions

Choosing the Right Track

Selecting the right friction drive track depends on your tractor’s horsepower and your specific application:

- Standard row crop tractors are well-suited for Trackman HP tracks

- Higher-demand tillage or construction applications benefit from the enhanced durability of Trackman HP Extreme tracks

Positive Drive

If your tractor uses a positive drive system, Trackman has the perfect solution for you. We were the first to market with a positive drive track on the Case 9300 model. As tractors evolved in horsepower and weight demands, we continued to lead with innovations like the ARMORLUG, followed by our latest design, ARMORLUG ULTRA.

Built to Outlast

All Trackman Positive Drive tracks deliver industry-leading longevity featuring reinforced construction that outlasts and outperforms in the toughest field conditions.

- Heavy-Pull Operations: Optimal performance in high-drawbar applications

- Precision Task: Enhanced control and reduced vibration.

- Demanding Terrain: Designed for challenging environments.

Each Trackman rubber track is designed for maximum resilience and performance:

- Improved Wheel Path Rubber: Minimizes abrasion and punctures.

- MAXXTUFF™ Steel Belting: Highest reinforcement for strength.

- ARMORLUG®/ARMORLUG® ULTRA: Enhanced lug durability options.

Comfort Meets Innovation

Experience unmatched operator comfort and precision with Trackman. Our industry-first Anti-Vibration Technology™ sets a new standard for positive drive tracks – delivering superior performance in heavy-pull applications and beyond.

Good: Trackman T600

- Made with proprietary MAXXTUFF ™ Steel Belting for unmatched lateral strength and durability

- Anti-Vibration Technology™ for smoother operation

- Brass-coated cables for corrosion resistance and extended life

- Fully molded tread lugs resist chunking and delamination

- Advanced wheel path rubber reduces abrasion and punctures, lowering cost per hour

Better: Trackman T700 ARMOURLUG®

- Includes all features of the T600

- Dual biased reinforcement plies surround each drive lug with 360° support

- Extends drive lug life by up to 23% over standard designs

- Comes with a 4-year prorated warranty for agricultural applications

Best: Trackman T800 ARMOURLUG® ULTRA

- Advanced patented ARMOURLUG® design

- Three layers of reinforcement fabric, including a top layer that extends into the wheel path

- Engineered to handle 25% more torque – ideal for high-horsepower applications

- Comes with an extended 5 year-prorated warranty for agricultural use

Choosing the Right Track

Now it’s time to choose the right track for you. The ideal track depends on your tractor’s capabilities and intended application.

- Lower-horsepower tractors, depending on manufacturer, are well suited for lighter tasks using Trackman T600 positive drive tracks

- Scraper applications typically require an upgrade to our T700 ARMORLUG tracks for enhanced durability and performance.

- Higher horsepower tractors and more demanding conditions, such as side hills, are best equipped with Trackman T800 ARMORLUG ULTRA tracks.

We encourage you to follow manufacturer guidance and visit our newly launched website for fitment details and product availability: TrackmanTracks.com

For best results and longer track life, refer to our Warranty Manual for application specific recommendations.

Camso

David Graden: Operational Market Manager – Agriculture

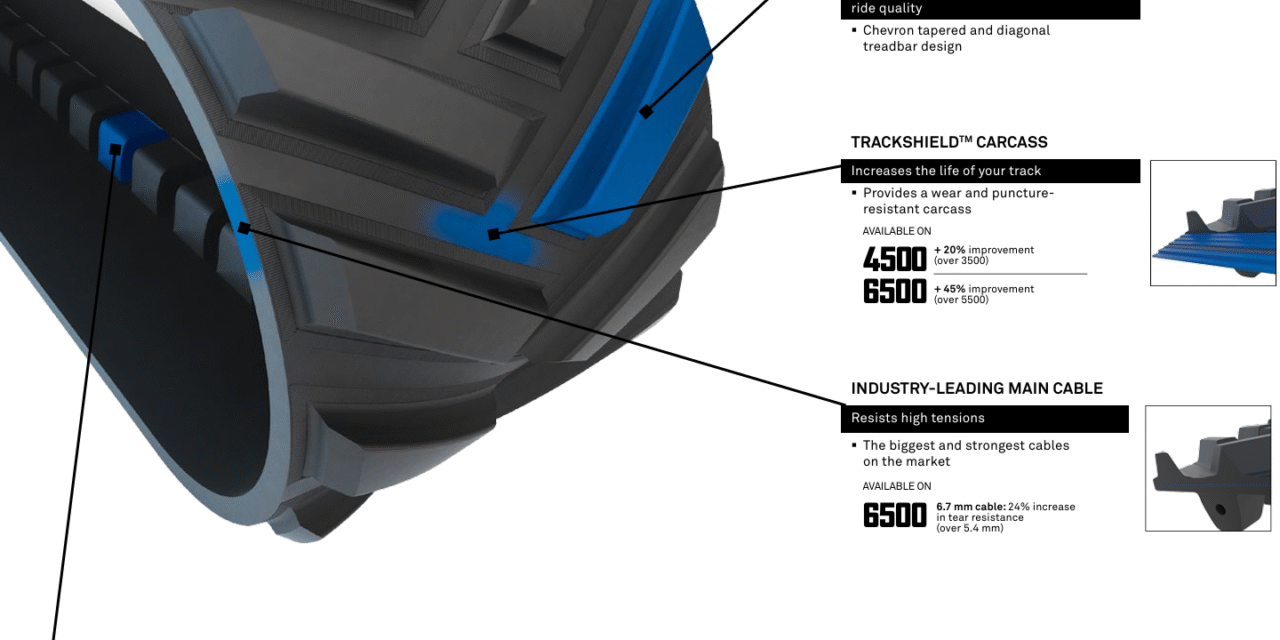

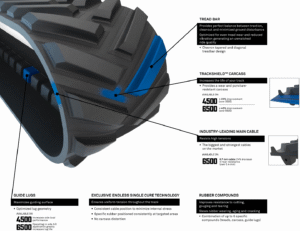

When it comes to Michelin’s Camso Ag tracks, there’s no one-size-fits-all solution. Camso offers a range of track qualities—from the 3500 Series all the way up to the 6500 Series—each designed to meet specific performance needs and budgets.

Let’s break it down:

Track Series Overview

- 3500 Series: This is Camso’s entry-level track—what they call the industry standard. It’s a solid option for general farming, especially if you’re running in lighter soils or flat terrain and not putting in extreme hours.

- 4500 Series: A step up in durability and performance. Camso says this redefines the industry standard, and I’d agree—it’s a great fit for row crop tractors and moderate to heavy use.

- 5500 Series: Built for high-hour operations and tougher conditions. If you’re running in abrasive soils or pulling heavy loads, this track will hold up better over time.

- 6500 Series: Top of the line. If uptime, longevity, and performance are critical to your operation—especially in extreme conditions—this is the track to go with.

Friction vs Positive Drive

Understanding your machine’s drive system is key to selecting the right track:

- Friction Drive: Common on machines like the Deere 8RT. These rely on surface contact between the drive wheel and the track. They’re simpler, but they don’t necessarily handle extreme torque as well as positive drive.

- Positive Drive: Found on machines like the Deere 8RX, Case IH QuadTrac, New Holland T9, Fendt 900 Vario MT, and Versatile DeltaTrack. These use lugs or teeth to engage the drive wheel, offering better torque transfer and reduced slippage—especially important for high-horsepower applications.

Machine Fitment Recommendations

Here’s what I recommend based on machine type and application:

John Deere

- 8RT (Friction Drive)

- Recommended Track: 4500 Series

-

- Why: Great balance of durability and value for row crop work and moderate field conditions.

- 8RX (Positive Drive)

- Recommended Track: 5500 or 6500 Series

- Why: With four tracks and high horsepower, you’ll want the added durability and traction of a premium track.

- 9RX (Positive Drive)

- Recommended Track: 6500 Series

- Why: This machine is built for extreme work. The 6500 Series will give you the best return on investment through longer life and fewer replacements.

Case IH Steiger QuadTrac (Positive Drive)

- Recommended Track: 6500 Series

- Why: High torque and heavy pulling demand the best track Camso offers.

New Holland T9 (Positive Drive)

- Recommended Track: 6500 Series

- Why: Similar to the QuadTrac—this machine needs a track that can take a beating and keep going.

Fendt 900 Vario MT (Positive Drive)

- Recommended Track: 4500 or 5500 Series

- Why: If you’re doing general fieldwork, the 4500 will do the job. For more aggressive applications, step up to the 5500.

Versatile DeltaTrack (Positive Drive)

- Recommended Track: 6500 Series

- Why: This machine is built for power and endurance. The 6500 Series is the best match for maximizing uptime and minimizing wear.

Final Thoughts

If you’re running moderate hours in good conditions, the 3500 or 4500 Series might be all you need. But if you’re pushing your equipment hard—high horsepower, tough terrain, long hours—investing in the 5500 or 6500 Series will pay off in the long run.