AG TRACK TALK KEY TAKEAWAYS

CAMSO: “When agricultural tracks are used for roading, heat becomes the single greatest threat to their longevity.”

AGRITRAXX: “Polyurethane undercarriage components run about 30% cooler in the hottest area of the wheel.”

TRACKMAN: “While ambient temperature, over an extended period may lead to increased surface temperature which can increase the temperature of a track, additional factors are important to understand…load on the vehicle and the duration of any roading would likely be higher contributing factors to heat build in a track.”

RUBBER TRACK SOLUTIONS: “The #1 Rule: Slow Down…Speed equals heat. When roading in hot weather: Keep speeds below 20 mph, avoid wide-open throttle, let the tractor cool down during long road hauls by stopping periodically for a quick inspection.

Camso

David Graden: Operational Market Manager – Agriculture

Why Ambient Temperature Matters When Roading Tracks

When agricultural tracks are used for roading, heat becomes the single greatest threat to their longevity. Friction between the track and the road surface generates heat, and when combined with high ambient temperatures, this can accelerate tread wear, soften rubber compounds, and even lead to premature failure of tracks and undercarriage components. As Jeff Staab, Michelin Ag’s Business Development Manager and former Camso Product Line Manager for Track Systems, explains:

“Growers are spending up to 15% of their time on the road during planting and harvest. Heat was the main challenge Camso engineers faced when developing high-speed roading solutions. Our approach was proactive—preventing heat buildup rather than just trying to dissipate it.”

Excessive heat compromises the integrity of the rubber carcass and bonding adhesives, and repeated heating and cooling cycles can destroy guide lugs and midrollers quickly. For this reason, monitoring temperature is essential. Carrying a handheld infrared temperature gun is a simple, effective way to check track and midroller temperatures during extended roading. If temperatures climb too high, it’s time to slow down or stop and allow the system to cool.

To optimize track life in high-roading applications, Camso recommends several best practices:

- Road at cooler times of the day: Whenever possible, schedule roading during cooler parts of the day to minimize heat stress.

- Reduce speed and load: Lower speeds significantly reduce frictional heat buildup. Most Camso track systems are rated for up to 20 mph for limited durations, but always confirm with your operator manual.

- Inspect the undercarriage regularly for signs of wear such as rubber chunking, cracks in guide lugs, or adhesive separation.

- Maintain proper track tension and alignment, as misalignment increases friction and heat.

- Choose the right surface: Gravel or dirt roads are preferable to pavement, which generates more heat. If you have the option, take one of these types of roads and you’ll possibly extend the life of your tracks.

Acceptable operating temperatures vary by model, but operators should keep track temperatures below levels where rubber softening occurs—typically under 180°F (82°C). Also keep in mind that the surface of the track may even be cooler than the inside of the track. Following these guidelines will help producers maximize track longevity and reduce the risk of heat-related failures during high-roading applications.

Why Camso Limits Speed—and the CTS High Speed Difference

Camso limits most agricultural tracks to 20 mph because higher speeds dramatically increase heat buildup, which can compromise rubber integrity and undercarriage components. However, Camso’s CTS High Speed Conversion Track System for combines is an exception. This system uses an integrated final drive to achieve up to 23 mph (37 km/h)—the fastest roading speed available for tracked harvesters—while maintaining durability and performance. This innovation addresses the growing need for faster transport during harvest without sacrificing reliability.

At Michelin owned Camso, our mission is to deliver track systems that perform reliably under the toughest conditions. By understanding how heat impacts your equipment and taking proactive steps to manage it, you can protect your investment and keep your operation moving efficiently.

Superior Tire & Rubber

Jerrod Ossa, Aftermarket Sales Manager – AgriTraxx® Undercarriage Wheels

The average farm size in the United States has been gradually increasing over the years. According to the USDA, the average farm size in 1935 was around 155 acres. Today, that number is closer to 466 acres. As farmers manage more acres, the distance from farms to fields continues to grow—meaning more time spent roading equipment between locations.

If you operate a track machine, you know that roading from field to field is one of the most demanding tasks on your tracks and undercarriage components. Heat is the number one enemy of track tractors, so what’s the best way to manage it and extend track life? One proven approach is switching your mid-rollers, idlers, and drive wheels to AgriTraxx® polyurethane.

At Superior Tire, we’ve spent more than a decade demonstrating that our polyurethane AG wheels are a leading solution for reducing heat and extending track life.

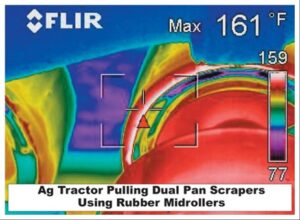

The photos above show the temperature difference between standard rubber wheels and Superior Tire’s polyurethane wheels in a heavy-duty pan scraping application. Polyurethane runs about 30% cooler in the hottest area of the wheel. This matters because the hottest point is where the bonding agent meets the material. Excess heat here can eventually lead to bond failure, meaning the rubber can separate completely from the steel casting.

One of my favorite real-world examples comes from a Texas producer. He had replaced mid-rollers on only one side of his STX Steiger with AgriTraxx® poly rollers. While roading to a field, he smelled burning and stopped immediately. The culprit? The rubber mid-rollers on the original side. When he checked the poly rollers, they were cool enough to touch—a clear sign that polyurethane dissipates heat far better than rubber, even during long road runs. That difference can provide peace of mind and help extend the life of your tracks.

Producers used to rely on talc powder or even cat litter to cool tracks and undercarriage components when using OEM rubber wheels. With polyurethane, those tricks aren’t necessary.

Does switching to AgriTraxx® poly wheels mean you can ignore best practices? Not at all. For long road runs, it’s still important to:

- Use gravel or dirt roads when possible to minimize heat buildup.

- Avoid heavy loads during extended roading.

- Keep tracks properly aligned to prevent unnecessary friction.

Ideal operating speed for track machines is 15–18 mph, depending on track condition and load.

Time is critical in farming, and one of the best ways to save both time and money is by using components designed for durability. At Superior Tire, we’re the only company in the industry offering a “No Bond Separation” guarantee—so you don’t have to worry about complete mid-roller, idler, or drive wheel failure.

Trackman

Tom Feldmann, Chief Manager of Engineering Development

While noting ambient temperature is a worthy consideration when getting ready to road your rubber track vehicle, focusing on ambient temperature alone can cause you to make decisions that are not in the best interest of your application and productivity and the cost impact of misusing your track equipment. While ambient temperature, over an extended period may lead to increased surface temperature which can increase the temperature of a track, additional factors are important to understand. Other factors like the load on the vehicle and the duration of any roading would likely be higher contributing factors to heat build in a track.

While it would be advisable to always carry an infrared thermometer temperature gun, the gun reading alone may provide you with a false sense of security in regard to any potential damage that may be advancing with your tracks. Internal track temperatures are of greater concern (and usually higher) than the surface reading you would get from a heat gun. The caution is that the temperature reading of a gun is not always directly linear with the surface temperature.

Major vehicle manufacturers typically work with their track suppliers in developing guidance as to load limits and roading duration that is acceptable for a vehicle while avoiding catastrophic damage to a track. These guidelines that are typically included in owner’s manuals should be read, understood and followed by ALL operators of the track equipment involved.

Another contributor to temperature builds in a track is alignment. Proper alignment will minimize the temperature build in the drive/guide lug areas of the track. Always follow manufacture guidance concerning alignment to maximize the track life. In addition, if you are working with new tracks that have been installed on your vehicle be certain to follow pre-conditioning procedures prior to any roading to reduce track temperature elevation.

Rubber Track Solutions

Jerry Von Gruenigen: V.P. Sales & Marketing

Why Ambient Temperature Matters

Rubber tracks are highly sensitive to ambient temperature. On 100-degree days, asphalt and concrete can exceed 140 °F, creating the perfect storm for rubber degradation.

As internal heat rises, the tread bars and roller path soften, the compounds begin to revert, and you’ll see accelerated wear – not only on the track surface but also across mid-rollers, drive lugs, and idlers.

The #1 Rule: Slow Down

Speed equals heat. When roading in hot weather:

- Keep speeds below 20 mph.

- Avoid wide-open throttle.

- Let the tractor cool down during long road hauls by stopping periodically for a quick inspection.

Slowing down reduces friction, lowers internal temperature, and prevents “reversionary wear”- the chemical breakdown that causes tread blocks to glaze, melt, or shed rubber.

Track Design and Application Matter

Not all tracks are built for the same purpose.

- Road-friendly tracks feature shorter, wider tread blocks and harder rubber compounds designed for sustained contact on pavement.

- Field-optimized tracks have taller, narrower tread bars with greater pitch spacing to dig and clean better in soil – but they run hotter and wear faster on the road.

If most of your operating hours involve road transport, choose a track engineered for high-roading applications to get better longevity and smoother performance.

Should You Carry a Temperature Gun?

A temperature gun isn’t mandatory – but it’s a smart diagnostic tool.

Checking surface temps periodically lets you spot hot spots before they cause serious wear. Consistent readings above 180–200 °F on the tread bar or roller path signal it’s time to stop, cool down, and inspect.

Pro Tips to Reduce Road Wear

- Follow Manufacturer Guidelines

Always reference your tractor’s service manual for maximum transport speeds, load limits, and cooling recommendations. - Add Dry Lubricity to the Undercarriage

Toss a handful of floor-dry, cat litter, or air-seeder talc into the undercarriage to create a dry film that reduces friction and heat buildup. - Lighten the Load

Empty saddle tanks and sprayer implements before roading. Extra weight increases rolling resistance and accelerates heat buildup. - Upgrade Mid-Rollers

If your machine still runs rubber mid-rollers, consider switching to polyurethane compounds – they handle heat and load far better during long road hauls. - Inspect Early and Often

Look for:- Soft, tacky guide blocks

- Melting or shiny tread surfaces

- Rubber droplets on roller paths

- Burning-rubber smell or smoke

- These are all signs of excess heat, not necessarily alignment failure.

Final Thoughts

Track tractors love dirt – they don’t love pavement.

If you’re roading frequently, treat heat management as part of your maintenance routine. Slow down, lighten up, keep the undercarriage cool, and you’ll save thousands in premature wear and downtime.