QUESTION:

Why are we seeing a shift on the new latest development of large Combines (Deere X9 / CNH 250 Series / AGCO 9T) from tires to tracks on front axle?

Soucy Track

Marc McDonald, Territory Manager

As with anything, sometimes more is better, but sometimes more comes with some real and unavoidable realities.

Machinery is getting larger. There isn’t really any way around it. Demand for productivity is at an all time high. Farms are bigger, yields are higher, and the demand to produce more to maintain profitability with equipment costs and low grain prices leaves little room for error.

New combines have more horsepower, more capacity, more productivity, more weight, and ultimately more problems supporting loads in compromising situations.

The input costs of today’s farm have skyrocketed. The price of fuel, land-forming, and time wasted on labor to repair needless soil damage all take from the bottom line.

These new combines are very heavy, so limited tire options that can even carry the weight of a loaded combine with a 16 row folding corn head are even available.

These needs pushed for tire manufacturers to produce IF tires (Increased Flexion) and VF tires (Very Increased or Very High Flexion) to be able to not only support the load but to improve the construction of the tires to be able to use lower pressures and increase the load support. CFO, meaning cyclical field operation, is the term used for the ability of the tire to go from low loads/higher speeds to high loads/lower speeds. The ability to do this accurately requires changing air pressures as load and speeds change between field conditions, loads, and transport.

Even with this improving technology, many combine manufacturers are trying to keep up with the need for a better and adequate support platform. What is the solution?

Tracks.

Tracks have unmatched support.

Tracks provide two to three times the ground contact as the largest tire configurations. This will bring ground pressures down from worse case situations of 40 psi down to a manageable 10-12 psi depending on track and combine.

Tracks have come through a long evolution. Originally tracks were adapted for worst case scenarios, but now have gone through the same technology improvements, giving big combines the needed solutions to do what they do best, perform.

Consideration for tracks now is now a more critical decision. With heavier combines, productivity is more and more dependent on conditions than ever before. If conditions are perfect, great. But more times than not, conditions are less than desirable and sometimes unexpected. A parked combine is a problem.

Plan for the unplanned. Expect the unexpected. That threshold is closer than ever.

The need for tracks is bigger than the weather emergency.

Tracks reduce the soil ground pressure, reducing tillage needs, improving crop yield losses to compaction, and improving the use of sustainable farming methods conducive to yield gains.

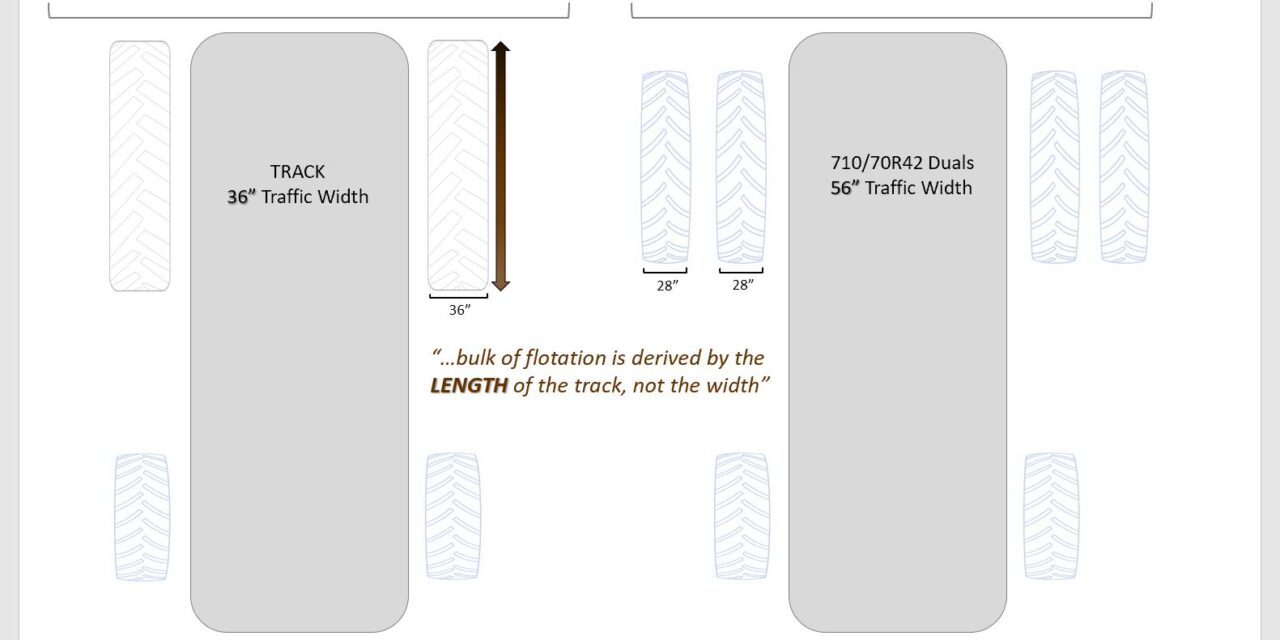

Tracks reduce trafficked area while harvesting. By eliminating the use of duals, the surfaced travelled is reduced to 36″ paths versus 4 tires. This also narrows transport widths of the combine with the headers removed providing a safer and more manageable move of larger combines from field to field.

The future of tracks on large combines is here.

I think it is easy to see and easier to say, tracks are proving they are here to stay.

Continental

Rob Schultz: Marketing Communications Americas

Using Track in Combine application is growing in popularity as front axles for this equipment carry some of the heaviest loads in ag work- soil compaction can be a huge problem, and having adequate flotation is critical.

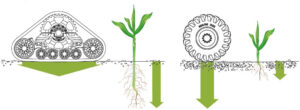

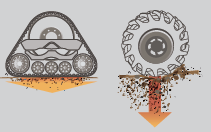

Tracks can provide larger footprint to help minimize the soil compaction, but do it differently than tires. We all know the bulk of soil compaction happens on the first pass. The difference with tracks is that bulk of flotation is derived by the length of the track, not the width, thus reducing the total amount of area trafficked during harvest.

Below width difference illustration shows how total area trafficked during harvest can be reduced:

Traction is another benefit for combines in North America as the extremely long footprint maximizes contact with the soil, as shown below with tire at typical air pressure.

With the scenario above, farmers are able to harvest corn later in the year as the fall weather degradates, minimizing soil compaction up to 65%.